The United States Mint produces dimes, each having a face value. Determining how much is two dimes involves basic arithmetic. Coin collecting, a hobby tracked by organizations like the American Numismatic Association (ANA), often values coins beyond their face worth. Thus, while the numerical answer to how much is two dimes is straightforward, economic principles regarding inflation impact its purchasing power. Calculating two dimes is simple but applying the concept to larger sums is essential for financial literacy.

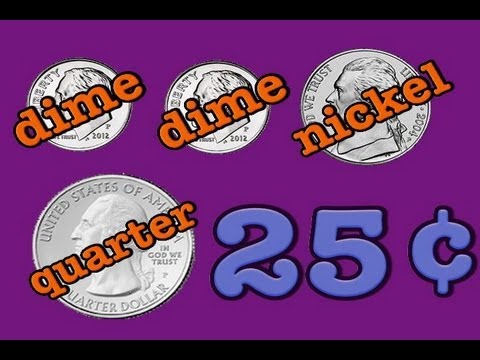

Image taken from the YouTube channel Mr. R.’s Songs for Teaching , from the video titled 2 Dimes and a Nickel- A Money Math Song .

Home canning offers a time-honored method for preserving the bounty of the garden and the flavors of the season. It’s a process that allows you to safely and effectively store food at home.

From fruits and vegetables to jams, jellies, and even meats, home canning empowers you to extend the shelf life of your favorite foods while controlling the ingredients and processes involved.

A Glimpse into Canning’s Past

The practice of preserving food through canning dates back to the early 19th century, driven by the need to feed armies and explorers. Nicolas Appert, a French confectioner, pioneered the technique of heating food in sealed glass jars to prevent spoilage.

This revolutionary method laid the foundation for modern canning practices, evolving from glass jars to tin-plated steel cans and eventually to the jars and equipment we use today. While the core principles remain the same, safety standards and scientific understanding have significantly advanced.

Why Can at Home? Unveiling the Benefits

Home canning presents a multitude of advantages for the modern food enthusiast:

- Cost Savings: Preserving seasonal produce at its peak ripeness can significantly reduce grocery bills, especially for those with gardens or access to local farms.

- Ingredient Control: Home canning allows you to dictate exactly what goes into your food, eliminating artificial preservatives, excessive sodium, and unwanted additives.

- Reduced Food Waste: Canning provides a practical solution for preventing food spoilage, transforming surplus produce into shelf-stable goods that can be enjoyed throughout the year.

- Customized Flavors: Experiment with different recipes, spices, and herbs to create unique flavor combinations that suit your individual tastes.

Water Bath vs. Pressure Canning: Choosing the Right Method

Not all canning methods are created equal. The two primary techniques are water bath canning and pressure canning, each suited for different types of foods.

- Water bath canning is appropriate for high-acid foods such as fruits, jams, jellies, pickles, and tomatoes with added acid. The high acidity inhibits the growth of harmful bacteria.

- Pressure canning is essential for low-acid foods like vegetables, meats, poultry, and seafood. These foods require higher temperatures than boiling water can achieve to eliminate the risk of botulism.

Setting Realistic Expectations

Home canning is a rewarding but detail-oriented process. It is crucial for beginners to approach it with patience, a willingness to learn, and an unwavering commitment to safety.

Start with simple recipes and gradually progress to more complex ones as you gain experience. Always use tested recipes from reputable sources such as the USDA or Ball.

Following instructions meticulously is non-negotiable in home canning. Any deviation from tested procedures can compromise the safety and quality of the preserved food. With careful preparation and adherence to established guidelines, home canning can become a fulfilling and sustainable way to enjoy the fruits (and vegetables) of your labor.

Home canning, with its promise of garden-fresh flavors year-round, is undeniably appealing. But beneath the allure of homemade goodness lies a critical need for vigilance.

Safety First: Understanding the Risks and Precautions

The art of home canning isn’t just about preserving food; it’s about preserving it safely. This aspect cannot be overstated. Neglecting proper techniques can lead to serious health risks, turning a delightful endeavor into a dangerous gamble.

The Specter of Botulism

Botulism, a severe and potentially fatal form of food poisoning, looms large in the world of home canning. It is caused by the bacterium Clostridium botulinum, which thrives in low-oxygen environments, like improperly canned foods.

This bacterium produces a potent neurotoxin that can cause paralysis, respiratory failure, and even death. Because C. botulinum spores are heat-resistant, they require specific canning methods to be eliminated.

Improper canning practices, such as inadequate processing times or using the wrong canning method, can create the perfect conditions for botulism to flourish. Other foodborne illnesses, though perhaps less deadly, can also result from poor sanitation and inadequate heating.

The Gospel of Tested Recipes

In the realm of home canning, not all recipes are created equal. Relying on untested recipes, passed down through generations or found on unreliable websites, is akin to navigating a minefield blindfolded.

Always adhere to tested recipes from reputable sources. Organizations like the U.S. Department of Agriculture (USDA) and companies like Ball meticulously research and test their recipes to ensure safety and efficacy.

These recipes provide precise instructions for processing times, jar sizes, and ingredient ratios, all crucial for eliminating harmful bacteria and creating a safe, shelf-stable product. Deviating from these tested recipes can compromise the safety of your canned goods.

High-Acid Versus Low-Acid: A Crucial Distinction

The acidity of food plays a pivotal role in determining the appropriate canning method. Foods are generally classified as either high-acid or low-acid.

High-acid foods, such as fruits, jams, jellies, and pickles, can be safely processed using a water bath canner. The high acidity inhibits the growth of C. botulinum.

Low-acid foods, including vegetables, meats, poultry, and seafood, require the higher temperatures achieved in a pressure canner to eliminate C. botulinum spores.

Understanding Acidity Levels

Acidity is measured on the pH scale, with values below 7 considered acidic and values above 7 alkaline. Foods with a pH of 4.6 or lower are considered high-acid.

Examples of High-Acid and Low-Acid Foods

- High-Acid Foods: Apples, berries, cherries, peaches, plums, tomatoes (some varieties require added acid), jams, jellies, pickles, sauerkraut.

- Low-Acid Foods: Green beans, corn, peas, carrots, spinach, mushrooms, meats, poultry, seafood, soups (unless acidified).

Using a water bath canner for low-acid foods is extremely dangerous and can result in botulism. The heat will not be high enough to kill the botulism spores.

Sterilization: A Foundation of Safety

Proper sterilization of jars and equipment is another cornerstone of safe home canning. Sterilizing jars eliminates any existing microorganisms that could contaminate the food and lead to spoilage.

Jars should be sterilized by boiling them in water for 10 minutes prior to filling. Lids should also be simmered (not boiled) in hot water to soften the sealing compound.

While some modern recipes suggest that sterilization is only necessary for processing times under 10 minutes, it’s best to err on the side of caution and sterilize all jars, regardless of processing time. Cleanliness is key throughout the entire canning process, from washing produce to sanitizing work surfaces.

Gather Your Gear: Essential Canning Equipment

After understanding the critical importance of safety, the next logical step in mastering home canning is assembling the right tools. Having the correct equipment not only makes the process easier and more efficient but also contributes significantly to the safety and quality of your preserved goods.

The Canning Arsenal: A Comprehensive List

To embark on your canning journey, you’ll need a specific set of tools. Each item plays a crucial role in ensuring the success and safety of the process.

- Canning jars (various sizes)

- Canning lids and bands

- Water bath canner or pressure canner

- Jar lifter

- Canning funnel

- Bubble remover/headspace tool

- Large pot for heating water

- Kitchen towels

Decoding the Tools of the Trade

Let’s examine each piece of equipment in more detail, highlighting its purpose and importance.

Canning Jars: The Vessels of Preservation

Canning jars are specially designed glass containers made to withstand the high temperatures of the canning process. They come in various sizes (pint, quart, half-gallon) to accommodate different types of food. Ensure that you only use jars specifically made for canning, as other glass containers may shatter under heat.

Canning Lids and Bands: Sealing in Freshness

These two-part lids are essential for creating an airtight seal. The flat lid has a sealing compound that adheres to the jar rim during processing. The metal band secures the lid during processing and is removed after the jar has cooled and sealed. Always use new lids for each batch, as the sealing compound can degrade after use. Bands can be reused if they are not damaged or rusty.

Water Bath Canner vs. Pressure Canner: Choosing the Right Method

The choice between a water bath canner and a pressure canner depends on the acidity of the food you’re preserving. A water bath canner is used for high-acid foods (pH of 4.6 or lower), like fruits, jams, jellies, and pickles. A pressure canner is essential for low-acid foods (pH higher than 4.6), such as vegetables, meats, and poultry. Using the wrong canner can lead to botulism, a potentially fatal form of food poisoning.

Jar Lifter: Handling Hot Jars with Care

A jar lifter is a specialized tool designed to safely lift hot jars from the canner. It features rubber-coated tongs that grip the jar securely, preventing slips and burns. Never attempt to lift hot jars with your bare hands or ordinary kitchen tongs.

Canning Funnel: Spill-Proof Filling

A canning funnel helps you fill jars without making a mess. Its wide mouth and narrow spout fit snugly into the jar opening, preventing spills and ensuring accurate filling.

Bubble Remover/Headspace Tool: Ensuring Proper Headspace

This tool is used to remove air bubbles from the jar after filling and to measure the headspace (the space between the top of the food and the jar lid). Proper headspace is crucial for creating a vacuum seal. A plastic knife or spatula can also work in place of a dedicated bubble remover.

Large Pot for Heating Water: Prepping the Bath

A large pot is needed to heat water for sterilizing jars and preheating lids. It doesn’t need to be fancy, any stockpot big enough to hold enough water to completely cover the jars should be sufficient.

Kitchen Towels: Cleanliness and Safety

Clean kitchen towels are essential for wiping jar rims, handling hot jars, and cleaning up spills.

Budget-Friendly Alternatives

While specialized canning equipment is ideal, there are affordable alternatives for some items. For example, a large stockpot with a rack can be used for water bath canning, provided it is deep enough to completely submerge the jars in boiling water with at least 1-2 inches above the top of the jars.

Water Bath Canning: A Step-by-Step Guide

With your equipment gathered and safety protocols firmly in mind, you’re ready to begin the canning process. Water bath canning is a straightforward method ideal for preserving high-acid foods like jams, jellies, pickles, and many fruits. This method uses boiling water to create a vacuum seal, preventing spoilage.

Here’s a detailed, step-by-step guide to ensure your success:

Step 1: Prepare the Jars

Sterilization is Key

Before you even think about your produce, the jars must be sterilized to eliminate any lingering bacteria or mold. The jars can be sterilized by boiling them in a water bath canner for 10 minutes.

Keep the jars in the hot water until ready to fill. This helps prevent them from cracking when filled with hot food.

Preheating for Success

Preheating the jars is just as important as sterilizing them. This prevents the jars from shattering when filled with hot contents.

You can preheat them by keeping them in the hot water after sterilizing or by placing them in a warm oven (200°F/93°C) until needed.

Step 2: Prepare the Food

Recipe Adherence

This step is all about following your chosen recipe precisely. Wash your fruits or vegetables thoroughly, chop them as directed, and cook according to the recipe’s instructions.

Precise measurements are crucial, especially when making jams and jellies, as they affect the setting properties.

Step 3: Fill the Jars

Headspace Matters

Carefully ladle the prepared food into the sterilized and preheated jars. The key here is leaving the correct amount of headspace – the empty space between the top of the food and the jar rim.

The recipe should specify the appropriate headspace, typically ranging from ¼ inch to ½ inch, depending on the food.

Why Headspace?

Headspace allows for proper expansion of the food during processing and helps create a strong vacuum seal as the jars cool. Insufficient headspace can lead to seal failures.

Step 4: Remove Air Bubbles and Adjust Headspace

Bubble Patrol

Air bubbles trapped inside the jar can compromise the seal. Use a bubble remover tool (or a clean, non-metallic spatula) to gently release any trapped air.

Run the tool around the inside edge of the jar. After removing bubbles, recheck the headspace and adjust if necessary by adding more food.

Step 5: Wipe Jar Rims and Apply Lids and Bands

Cleanliness Counts

A clean jar rim is crucial for a proper seal. Use a clean, damp cloth to thoroughly wipe the rim of each jar, removing any food residue.

Even a tiny speck of food can prevent the lid from sealing correctly.

Lid Application

Place a new, unused lid on each jar, ensuring the sealing compound makes full contact with the rim. Screw on the metal band finger-tight.

Avoid overtightening the bands, as this can prevent air from escaping during processing and lead to buckling or seal failures.

Step 6: Process in the Water Bath Canner

Submersion is Essential

Carefully lower the filled jars into the water bath canner, ensuring they are completely submerged under at least 1-2 inches of water.

Use a jar lifter to avoid burns and prevent damage to the jars.

Timing is Everything

Bring the water to a rolling boil, then begin timing the processing according to your recipe. Processing times vary depending on the type of food and the jar size.

Adjust processing times for altitude, as water boils at lower temperatures at higher elevations, requiring longer processing.

Step 7: Remove Jars and Cool

Gentle Handling

Once the processing time is complete, turn off the heat and carefully remove the jars from the canner using the jar lifter.

Place the jars on a towel-lined surface, leaving at least an inch of space between them.

Undisturbed Cooling

Allow the jars to cool undisturbed for 12-24 hours. Do not tighten the bands or invert the jars during this time.

As the jars cool, you should hear a "pop" sound as the lids seal.

Step 8: Check Seals and Store Properly

The Seal Test

After the jars have cooled completely, check the seals. Press down on the center of each lid. If the lid doesn’t flex or move, it’s properly sealed.

If a lid flexes, it’s not sealed. Unsealed jars should be reprocessed with new lids or refrigerated and used within a few days.

Storage Matters

Remove the bands, wash the jars, label with the contents and date, and store in a cool, dark, and dry place. Removing the bands prevents rust from forming and obscuring a failed seal later.

Properly canned goods can last for up to a year. Always check for signs of spoilage before consuming.

With your high-acid goods safely tucked away thanks to water bath canning, it’s time to tackle foods that demand a little more muscle—and a lot more pressure. Preserving low-acid foods requires a different approach, one that reaches higher temperatures to eliminate the risk of botulism. That’s where pressure canning comes in, unlocking a world of preserved vegetables, meats, and poultry, all shelf-stable and ready to enjoy.

Pressure Canning: Mastering Low-Acid Foods

Pressure canning is essential for safely preserving low-acid foods.

These foods, including vegetables, meats, and poultry, require higher temperatures than boiling water can provide to eliminate the risk of botulism. Botulism is a serious and potentially fatal form of food poisoning.

Pressure canning achieves these higher temperatures, ensuring that the food is safe to eat. This method demands careful attention to detail and adherence to tested recipes to guarantee a safe and successful outcome.

Why Pressure Canning is a Must for Low-Acid Foods

Low-acid foods have a pH level greater than 4.6. This creates an environment where Clostridium botulinum spores can thrive and produce the deadly botulinum toxin.

Water bath canning, which relies on boiling water (212°F/100°C), doesn’t reach a high enough temperature to kill these spores.

Pressure canning, however, raises the temperature inside the canner to 240°F (116°C) or higher. This temperature effectively destroys the spores, rendering the food safe for long-term storage.

Step-by-Step Guide to Pressure Canning

Here’s a detailed guide to using a pressure canner safely and effectively. Always refer to your canner’s instruction manual and a tested canning recipe for specific instructions.

Preparing Jars and Food

This initial step mirrors the preparation process for water bath canning. Sterilize your jars and prepare your chosen low-acid food according to a tested recipe. This usually involves washing, chopping, and sometimes pre-cooking the food.

Adding Water to the Canner

Pour the amount of water specified in your recipe into the pressure canner. This water creates the steam necessary for pressure canning. Using the correct amount is crucial for proper heat distribution.

Loading the Jars

Carefully load the filled jars into the canner, using a jar lifter. Ensure the jars don’t touch each other or the sides of the canner. This allows for even heat circulation.

Sealing the Canner

Secure the lid of the pressure canner, following the manufacturer’s instructions. Ensure the lid is properly sealed to prevent steam from escaping prematurely.

Venting the Canner

Before pressurizing, vent the canner by allowing steam to escape for the time specified in your recipe (usually 10 minutes). Venting removes air from the canner, ensuring that the internal temperature accurately reflects the pressure.

Pressurizing the Canner

Close the vent and allow the pressure to build to the level specified in your recipe. Monitor the pressure gauge carefully. Adjust the heat to maintain the correct pressure throughout the processing time. Maintaining consistent pressure is critical for safety.

Depressurizing the Canner

Once the processing time is complete, turn off the heat and allow the canner to depressurize naturally. Do not force depressurization, as this can cause siphoning and seal failures. Once the pressure gauge returns to zero, wait 10 minutes before carefully opening the vent.

Removing Jars and Cooling

Carefully remove the jars from the canner using a jar lifter and place them on a towel-lined surface to cool undisturbed for 12-24 hours. Avoid moving or tilting the jars during this time.

Checking Seals and Storing

After cooling, check the seals of each jar. The lid should be concave and not flex when pressed. Store properly sealed jars in a cool, dark, and dry place.

Key Safety Precautions for Pressure Canning

- Always use a tested recipe from a reputable source. This ensures that the processing time and pressure are adequate for the specific food being canned.

- Follow your canner’s instruction manual carefully. Different canners have different operating procedures.

- Vent the canner properly. Failure to vent can result in inaccurate pressure readings and unsafe food.

- Monitor the pressure gauge closely. Maintaining consistent pressure is crucial for killing botulism spores.

- Do not force depressurization. Allow the canner to depressurize naturally to prevent siphoning and seal failures.

Pressure canning might seem intimidating at first, but with careful attention to detail and adherence to safety guidelines, you can safely preserve a wide variety of delicious and nutritious low-acid foods for your family to enjoy.

Troubleshooting: Addressing Common Canning Problems

Even with meticulous preparation and adherence to tested recipes, canning challenges can arise. Identifying these problems and understanding their causes is crucial for ensuring food safety and preventing future issues. This section addresses common canning problems, their causes, and practical solutions.

Common Canning Problems and Their Causes

Recognizing potential issues early allows for prompt corrective action, safeguarding your preserved goods.

Seal Failures

Seal failures are perhaps the most disheartening issue. Several factors can contribute to this problem:

- Improper Headspace: Insufficient headspace can prevent a vacuum from forming. Excessive headspace may lead to insufficient processing.

- Damaged Jar Rims: Nicks or cracks in the jar rim can prevent a proper seal.

- Food Particles on Rim: Food residue on the rim interferes with the lid’s ability to seal correctly.

- Worn-Out Lids: Reusing canning lids is not recommended, as the sealing compound degrades with each use.

- Loose Bands: Bands that are too loose during processing may not create a tight enough seal.

Cloudy Jars

Cloudy or murky contents can be visually unappealing, even if the food is safe.

Common causes include:

- Hard Water: Minerals in hard water can precipitate out, causing cloudiness.

- Starch in Food: Starchy vegetables or grains may release starch during processing, resulting in a cloudy appearance.

- Mineral Deposits: Naturally occurring minerals in some foods can contribute to cloudiness.

Siphoning

Siphoning refers to the loss of liquid from the jar during processing.

This can occur due to:

- Rapid Pressure Changes: Sudden changes in pressure, especially during cooling, can cause liquid to siphon out.

- Overfilling Jars: Excessive filling beyond the recommended headspace can also cause siphoning.

- Insufficient Venting: In pressure canning, improper venting can lead to siphoning.

Unusual Smells or Colors

Any unusual smell or color is a red flag and a clear indication of potential spoilage. Do not taste the food. Botulism doesn’t always cause noticeable changes, so err on the side of caution.

- Spoilage: These signs often indicate the growth of harmful bacteria, including Clostridium botulinum.

Solutions for Common Canning Problems

Addressing canning issues promptly is essential for preserving food safely.

- Seal Failures: If a jar fails to seal within 24 hours, you have a few options. You can reprocess the food with a new lid within 24 hours, refrigerate it for immediate use, or freeze it for longer storage. Always inspect the jar rim for damage before attempting to reprocess.

- Cloudy Jars: While often harmless, you can minimize cloudiness by using filtered water or adding a small amount of vinegar or lemon juice to the jar (following a tested recipe).

- Siphoning: Ensure proper headspace and avoid sudden pressure changes during cooling. Follow your canner’s instructions carefully regarding venting and depressurization.

- Unusual Smells or Colors: Discard any jars exhibiting unusual smells or colors immediately. Never taste food from a jar with signs of spoilage. Dispose of the contents in a sealed bag in the trash to prevent accidental consumption by pets or wildlife. Clean and sanitize any surfaces that came into contact with the spoiled food.

Testing Seals Correctly

Properly testing seals is crucial to confirm the success of the canning process.

After the jars have cooled completely (12-24 hours), remove the bands. Do not retighten bands after processing.

Then:

- Press the Lid: Press down on the center of the lid. If it flexes or pops, the jar is not sealed.

- Tap the Lid: Tap the lid with a metal spoon. A clear, high-pitched sound indicates a good seal. A dull thud suggests a failed seal.

- Lift by the Lid: Carefully lift the jar by the edges of the lid. If the seal is good, the lid should hold the jar securely.

If a jar fails any of these tests, it is not properly sealed and should be reprocessed, refrigerated, or frozen. Properly sealed jars can be stored in a cool, dark, and dry place for optimal shelf life.

Storage and Shelf Life: Ensuring Long-Term Preservation

Having navigated the canning process and successfully sealed your jars, the next critical step is proper storage. Correct storage techniques safeguard your preserved goods, ensuring their quality and safety for consumption. Understanding recommended shelf life, labeling, and spoilage signs are also paramount for a successful and safe canning experience.

Optimal Storage Conditions

Canned goods thrive in cool, dark, and dry environments. These conditions minimize the risk of spoilage and maintain the quality of your preserved food.

Avoid storing jars in areas prone to temperature fluctuations, such as near ovens, stoves, or in direct sunlight.

Excessive heat can degrade the food quality and potentially compromise the seal.

Damp environments can lead to rust on the lids and bands, potentially affecting the seal’s integrity.

Basements and pantries are often ideal storage locations, provided they are dry and maintain a relatively consistent temperature.

Recommended Shelf Life

While properly canned goods can last for years, it’s generally recommended to consume them within one year for optimal quality.

After this period, the food may still be safe to eat if the seal remains intact and there are no signs of spoilage, but the flavor, texture, and nutritional value may decline.

Think of it like this: your canned goods won’t suddenly become inedible after 12 months, but their peak freshness and deliciousness are best enjoyed within that timeframe.

The Importance of Labeling

Labeling your jars with the date and contents is essential for effective stock rotation and inventory management.

This practice prevents confusion and ensures that you use the oldest items first.

Use a permanent marker to clearly write the date (month and year) and the name of the contents on the lid.

Consider adding any specific details about the recipe or ingredients, such as "low sugar" or "organic," to aid in selection later on.

Stock Rotation: First In, First Out (FIFO)

Implement a "first in, first out" (FIFO) system for your canned goods.

This means placing newly canned items at the back of the storage area and bringing older jars to the front.

This ensures that you consume the oldest items first, maximizing their quality and minimizing the risk of spoilage.

Regularly check your stock and rearrange jars as needed to maintain the FIFO order.

Inspecting for Spoilage: What to Look For

Before opening any jar of home-canned goods, carefully inspect it for signs of spoilage.

Do not consume the contents of any jar that exhibits any of the following warning signs:

- Bulging Lids: This indicates that pressure has built up inside the jar, potentially due to bacterial growth.

- Unusual Smells: A foul or “off” odor upon opening the jar is a clear indication of spoilage.

- Cloudy Liquid: While some cloudiness can be normal, excessive cloudiness or sediment may indicate a problem.

- Visible Mold: Any sign of mold growth, whether on the lid or inside the jar, is a sign of spoilage.

- Forced Air/Spray: A hissing sound when opening a jar can mean potential spoilage.

If you observe any of these signs, discard the jar immediately without tasting the contents. For safety, it is recommended to dispose of potentially spoiled canned goods in a sealed bag in the outside trash to prevent consumption by animals.

Unlock Two Dimes: Frequently Asked Questions

Here are some common questions about the value of two dimes and how they measure up.

What exactly does "unlock two dimes" mean?

"Unlock two dimes" is just a catchy way of referring to having 20 cents. Two dimes, each worth 10 cents, add up to 20 cents.

So, how much is two dimes worth in total?

Two dimes are worth 20 cents. That’s the basic value of two US dimes combined.

Why would someone talk about "unlocking" two dimes instead of just saying "20 cents"?

It’s likely used to emphasize a small amount that can be used for something, like unlocking a discount, a digital reward, or some other small benefit. It’s more of a marketing or promotional phrase.

Can two dimes buy anything significant these days?

While two dimes or 20 cents might not seem like much, it can still be enough to cover small purchases, like a piece of candy, a short song download, or contribute to a larger purchase through a rewards program. Keep in mind that how much two dimes can buy depends on where you are.

So, now you know the deal! Figuring out how much is two dimes might seem small, but it’s a step in understanding bigger money things. Hope you found this helpful!