The internal combustion engine relies heavily on precise timing, a concept integral to understanding the firing order for big block chevy. The correct firing order – often 1-8-4-3-6-5-7-2 for many big block Chevy engines – ensures balanced crankshaft rotation. Proper installation is crucial to prevent engine damage or performance issues, requiring knowledge of both the distributor and its relation to the engine’s cylinders. General Motors designed various big block Chevy engines, each requiring adherence to the specified firing order for big block chevy to achieve optimal operation.

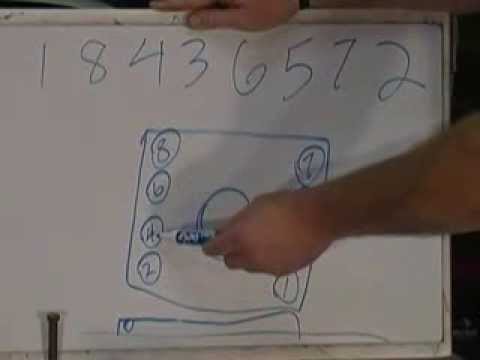

Image taken from the YouTube channel MintHillBilly DIY , from the video titled How to : Small or Big Block Chevy Firing Order Explained .

The rumble of a Big Block Chevy is a sound many enthusiasts recognize, a testament to raw power and engineering prowess. But beneath that roar lies a carefully orchestrated sequence of events, a precise ballet of combustion that dictates the engine’s performance and longevity. This sequence is known as the firing order, and understanding it is paramount to appreciating—and maintaining—the heart of these iconic engines.

The Foundation of Function: Why Firing Order Matters

At its core, the firing order is the sequence in which the cylinders of an internal combustion engine ignite their air-fuel mixture, driving the pistons and ultimately turning the crankshaft. It’s not a random occurrence; rather, it’s a meticulously designed pattern intended to optimize engine balance, minimize vibrations, and maximize power output.

A properly executed firing order ensures that the engine operates smoothly and efficiently. Without it, an engine will misfire, run rough, or, in severe cases, fail to start altogether.

Imagine an orchestra where the instruments play out of sync – the result would be cacophony, not music. The firing order is the conductor ensuring each cylinder plays its part at the precise moment.

Unleashing Potential: Firing Order and Engine Performance

The correct firing order isn’t just about preventing catastrophic failure; it’s also about unlocking the engine’s full performance potential. A well-defined firing sequence contributes to:

- Balanced crankshaft rotation: Reducing stress and wear on engine components.

- Efficient exhaust scavenging: Promoting better cylinder filling for the next combustion cycle.

- Minimized engine vibrations: Enhancing driver comfort and reducing component fatigue.

- Optimized power delivery: Ensuring that power is delivered smoothly and consistently throughout the RPM range.

By adhering to the correct firing order, the Big Block Chevy engine can deliver the kind of exhilarating performance that made it a legend.

A Legacy of Power: Introducing the Big Block Chevy

The Big Block Chevy engine family represents a significant chapter in automotive history. Introduced in the late 1950s, these engines quickly became synonymous with power and performance, finding their way into everything from Chevrolet’s muscle cars to heavy-duty trucks.

Their large displacement, typically ranging from 396 to 454 cubic inches (and beyond in modified applications), allowed them to generate prodigious amounts of torque, making them ideal for hauling heavy loads or propelling vehicles to blistering speeds.

The Big Block Chevy’s enduring popularity stems from its robust design, its potential for modification, and its proven track record on both the street and the racetrack. Understanding the intricacies of its firing order is critical to preserving and maximizing the performance of these iconic engines for generations to come.

The correct firing order isn’t just about preventing catastrophic failure; it’s also about unlocking the engine’s full performance potential. A well-defined firing sequence contributes to balanced crankshaft rotation, efficient exhaust scavenging, and minimized engine vibrations. Now, let’s shift our focus to the powerhouse itself: the Big Block Chevy engine. What exactly defines this iconic piece of American automotive engineering, and why has it remained so revered for decades?

What is a Big Block Chevy Engine? Defining the Beast

The term "Big Block Chevy" evokes images of roaring muscle cars and high-performance trucks, instantly recognizable to any automotive enthusiast. But what actually defines a Big Block Chevy engine? It’s more than just displacement; it’s a legacy of power and engineering ingenuity.

An Overview of Chevrolet Big Block Engines

The Chevrolet Big Block engine family represents a line of large displacement, overhead valve (OHV) V8 engines produced by General Motors from the mid-1950s through the late 2000s. These engines were designed to deliver significant power and torque, making them ideal for vehicles requiring substantial performance capabilities.

Unlike their smaller sibling, the Small Block Chevy, Big Blocks were conceived for heavier-duty applications, offering increased displacement and robust construction.

They powered everything from passenger cars and trucks to boats and industrial equipment.

The Significance of Big Blocks in Classic Chevy Vehicles

Big Block engines played a pivotal role in shaping the performance landscape of classic Chevy vehicles. Models like the Corvette, Camaro, Chevelle, and Impala were often equipped with these formidable engines, transforming them into legendary muscle cars.

The availability of a Big Block option often signified the highest performance variant of a particular model.

These engines not only provided exhilarating acceleration and top speed but also contributed to the cultural identity of these vehicles. The raw power and distinctive sound of a Big Block became synonymous with American automotive muscle.

Displacement Sizes and Common Applications

Big Block Chevy engines came in a variety of displacement sizes, each tailored for specific applications.

The most common displacements include:

-

396 cubic inches (6.5 L): Introduced in 1965, it powered early muscle cars.

-

402 cubic inches (6.6 L): A bored-out version of the 396.

-

427 cubic inches (7.0 L): Famous for its high-performance applications.

-

454 cubic inches (7.4 L): The largest displacement offered in production passenger cars.

-

502 cubic inches (8.2 L): Primarily offered as a crate engine for performance enthusiasts.

These engines found their way into a wide range of vehicles. The smaller 396 and 402 cubic inch variants were often used in passenger cars and light-duty trucks. The larger 427 and 454 cubic inch engines were typically reserved for high-performance applications, such as Corvettes, Camaros, and heavy-duty trucks. The 502 cubic inch engine, being a crate engine, was primarily used in modified or custom vehicles seeking maximum power.

The Big Block Chevy engine, a symbol of American automotive muscle, owes much of its legendary performance to its meticulously designed firing order. But before we explore the specific sequence, let’s understand what "firing order" fundamentally means in the world of internal combustion.

Decoding the Firing Order: 1-8-4-3-6-5-7-2 Explained

In the intricate dance of an internal combustion engine, the firing order dictates the precise sequence in which each cylinder’s air-fuel mixture is ignited. This order is not arbitrary. It’s a carefully engineered sequence that profoundly impacts engine balance, efficiency, and overall performance.

What is the Firing Order?

Imagine each cylinder as a drummer in an orchestra. The firing order is the musical score, dictating when each drummer strikes their drum to create a harmonious rhythm. In an engine, this "rhythm" translates to the controlled explosions that drive the pistons and ultimately, the crankshaft.

The firing order is the sequence in which the spark plugs ignite the air-fuel mixture within each cylinder of the engine. It’s the choreography of combustion.

This sequence is crucial for a smooth and efficient power delivery. An incorrect firing order can lead to misfires, rough idling, reduced power, and even engine damage.

The Big Block Chevy Firing Order: A Closer Look

The Big Block Chevy engine, with its distinctive rumble and raw power, employs a specific firing order: 1-8-4-3-6-5-7-2. This seemingly random sequence is a masterpiece of engineering designed to optimize engine performance.

But what does this sequence mean in practice?

It means that cylinder number 1 fires first, followed by cylinder number 8, then cylinder number 4, and so on, until all eight cylinders have completed their combustion cycle.

To truly grasp the significance of this order, visualize the cylinders arranged in the engine block, with the distributor cap positioned to send the spark to each cylinder in this precise sequence.

Below is a typical representation of a Big Block Chevy’s cylinder layout and firing order:

Firewall

6 8

4 2

3 5

7 1

Front of engine

(Note: This diagram is representational. Consult a repair manual specific to your engine year and model for precise cylinder locations.)

The distributor rotor spins, making contact with each terminal on the distributor cap in the 1-8-4-3-6-5-7-2 order, sending the electrical pulse to the corresponding spark plug, igniting the air-fuel mixture.

The Engineering Behind the Sequence

Why this particular sequence? The 1-8-4-3-6-5-7-2 firing order is not a random selection. It is a product of careful engineering to achieve optimal engine balance and performance.

This specific order helps to distribute the combustion events evenly throughout the engine block. This minimizes vibrations and reduces stress on the crankshaft and other engine components.

By alternating firing between cylinders on opposite banks, the engine achieves a smoother and more balanced rotation. This balance is critical for reducing wear and tear, improving engine longevity, and enhancing overall performance.

Furthermore, the firing order influences exhaust scavenging. The sequence helps to efficiently remove exhaust gases from each cylinder, optimizing the intake of fresh air-fuel mixture for the next combustion cycle. This contributes to increased power and improved fuel efficiency.

In essence, the 1-8-4-3-6-5-7-2 firing order is a carefully orchestrated sequence that unlocks the Big Block Chevy engine’s full potential.

Cylinder Number Identification: A Visual Guide

With the firing order sequence firmly in mind, the next crucial step is accurately identifying each cylinder on your Big Block Chevy engine. Misidentification can lead to incorrect spark plug wiring, resulting in misfires, poor performance, or even engine damage. Understanding the cylinder numbering convention is paramount for successful engine maintenance and tuning.

The Standard Cylinder Numbering Scheme

Big Block Chevy engines follow a standardized numbering system to designate each cylinder. This system is consistent across most V-style engines, making it relatively easy to learn. However, paying close attention to the orientation of the engine is critical to avoid mistakes.

The key is to visualize the engine as if you were sitting in the driver’s seat. The cylinders are numbered sequentially, starting from the front of the engine.

- On the right (passenger side) bank, the cylinders are numbered 1, 3, 5, and 7, starting from the front.

- On the left (driver’s side) bank, the cylinders are numbered 2, 4, 6, and 8, again starting from the front.

(Include a clear diagram here showing the standard Cylinder Numbers on a Big Block Chevy engine. The diagram should clearly label each cylinder number on both banks of the engine. It is advisable to provide multiple views, especially if the cylinder arrangement is unique.)

Why Accurate Cylinder Identification Matters

Correctly identifying each cylinder is not merely an academic exercise. It has direct, practical implications for engine operation.

The spark plug wires must be connected to the correct cylinders in accordance with the firing order. A single misplaced wire will disrupt the combustion process. This results in a misfire and can cause the engine to run roughly or not at all.

Furthermore, many diagnostic procedures and engine adjustments require knowing the precise location of each cylinder. Whether you’re setting valve lash, checking compression, or troubleshooting a specific cylinder, accurate identification is essential.

Bank 1 vs. Bank 2: Understanding the Terminology

The terms "Bank 1" and "Bank 2" are frequently used when discussing engine diagnostics and repairs, particularly in relation to sensor locations and fault codes. It’s important to understand what these terms refer to.

- Bank 1 generally refers to the bank of cylinders that contains cylinder number 1. On a Big Block Chevy, this is the right (passenger side) bank.

- Bank 2 is the opposite bank, or the left (driver’s side) bank.

This designation is particularly relevant when dealing with oxygen sensors (O2 sensors) and other engine management components that are bank-specific. For example, an O2 sensor code referencing "Bank 1" indicates a problem with the sensor located on the side of the engine where cylinder number 1 is located.

The Distributor’s Role: Orchestrating the Spark

Having pinpointed each cylinder’s location, we turn our attention to the component responsible for delivering the lifeblood of combustion: the distributor. The firing order, meticulously detailed, is essentially a set of instructions. The distributor is the conductor, ensuring those instructions are executed flawlessly. It dictates when each cylinder receives its spark, transforming potential energy into raw power.

Distributing the Spark: A Symphony of Timing

The distributor’s primary function is to deliver a high-voltage spark to each cylinder at precisely the correct moment in the engine’s cycle. It acts as a rotary switch, connecting the ignition coil to each spark plug in the firing order sequence.

Inside the distributor, a rotating rotor arm spins in sync with the engine’s crankshaft. As the rotor arm passes each terminal inside the distributor cap, a high-voltage pulse is sent through the corresponding spark plug wire. This spark ignites the air-fuel mixture within the cylinder, initiating the power stroke.

The precise timing of this spark is critical. If the spark occurs too early or too late, combustion will be inefficient, leading to reduced power, poor fuel economy, and potential engine damage.

Distributor Cap Orientation and Terminal Connections

The distributor cap is more than just a protective cover; it’s the interface between the distributor and the spark plugs. The terminals within the cap are arranged in a specific order, corresponding to the engine’s firing order.

Connecting the spark plug wires to the correct terminals is absolutely essential. A mistake here will disrupt the firing sequence, causing misfires and severely impacting engine performance.

Always double-check the wiring diagram for your specific Big Block Chevy engine to ensure the spark plug wires are connected to the correct terminals on the distributor cap.

Think of it like connecting the right instruments to the right outputs on a music mixing board. If they’re not connected correctly, the music won’t sound good.

Setting the Distributor Timing: Achieving Optimal Performance

"Timing" refers to the moment the spark plug fires in relation to the position of the piston within the cylinder. Properly setting the distributor timing is crucial for achieving optimal engine performance, fuel efficiency, and minimizing emissions.

Understanding Base Timing

Base timing is the initial timing setting, typically specified in degrees Before Top Dead Center (BTDC). It is the foundation upon which the engine’s timing is built.

The Role of Advance

As engine speed increases, the timing needs to be advanced – meaning the spark plug needs to fire slightly earlier in the compression stroke. This is because at higher RPMs, the engine cycles faster, and the air-fuel mixture needs more time to fully combust. Distributors use mechanical and vacuum advance mechanisms to automatically adjust the timing based on engine speed and load.

Setting the Timing

Setting the distributor timing typically involves using a timing light to observe the position of the timing marks on the crankshaft pulley or harmonic balancer. The distributor is then rotated until the timing marks align with the specified BTDC setting at idle speed.

Improper timing can lead to a variety of problems, including pinging or knocking, reduced power, overheating, and even engine damage. Consulting your engine’s service manual or a qualified mechanic is highly recommended when setting the distributor timing.

Having pinpointed each cylinder’s location and understood the distributor’s role in orchestrating the spark, it’s time to focus on the final link in the chain: the spark plug wires themselves. These wires are the high-voltage conduits that deliver the precisely timed spark from the distributor to the spark plugs, igniting the air-fuel mixture and initiating the combustion process. Connecting these wires correctly is not just important; it’s absolutely essential for proper engine operation.

Spark Plug Connections: Wiring it Right

The correct connection of spark plug wires to their corresponding cylinders is paramount to a Big Block Chevy’s performance and longevity. An improperly wired engine will run poorly, if at all, and can suffer serious internal damage. Therefore, meticulous attention to detail during this process is non-negotiable.

Connecting Spark Plugs to Cylinder Numbers: A Step-by-Step Guide

Connecting the spark plugs to the correct cylinder numbers might seem straightforward, but mistakes are surprisingly common. Here’s a detailed guide to ensure accurate connections:

-

Consult the Firing Order and Cylinder Layout: Have a clear diagram of the Big Block Chevy cylinder numbering and the 1-8-4-3-6-5-7-2 firing order readily available. This serves as your roadmap.

-

Locate Cylinder Number One: Identify cylinder number one, typically located at the front of the engine on the driver’s side. This is your starting point.

-

Trace the Distributor Cap: Find the terminal on the distributor cap that corresponds to cylinder number one in the firing order. This is where the spark plug wire for cylinder one will connect.

-

Connect the Wire: Securely attach the spark plug wire to both the distributor cap terminal and the spark plug for cylinder one. Ensure a firm, positive connection.

-

Repeat for Remaining Cylinders: Systematically repeat steps 3 and 4 for the remaining cylinders, always referencing the firing order and cylinder layout. Work methodically to avoid errors.

-

Double-Check Your Work: After connecting all wires, meticulously double-check each connection against your diagram. It’s far better to catch a mistake now than to experience engine problems later.

The Importance of Quality Spark Plug Wires

The spark plug wires are subjected to extreme conditions, including high voltage, heat, and vibration. Using high-quality wires is not a luxury; it’s a necessity.

Inferior wires can suffer from:

-

Reduced Conductivity: Leading to a weak spark and incomplete combustion.

-

Insulation Breakdown: Causing arcing and misfires.

-

Premature Failure: Resulting in frequent replacements.

Invest in spark plug wires from a reputable manufacturer and ensure they are designed for high-performance applications. Look for features like low resistance, high temperature insulation, and durable construction. Replacing the spark plug wires is a good practice during regular maintenance.

Inspecting Spark Plug Wires

Regularly inspect your spark plug wires for signs of damage, such as:

- Cracks or Tears: Indicating insulation breakdown.

- Burn Marks: Suggesting arcing.

- Loose Terminals: Causing poor connections.

- Stiffness or Brittleness: Signifying age and degradation.

Replace any wires that exhibit these symptoms immediately. It is also important to clean the terminals and ensure they are free from corrosion or debris.

Troubleshooting Misfires: When Things Go Wrong

Misfires are a common symptom of incorrect or faulty spark plug connections.

A misfire occurs when a cylinder fails to fire properly, resulting in:

- Rough Idling: An uneven and shaky engine idle.

- Reduced Power: A noticeable decrease in acceleration and overall performance.

- Poor Fuel Economy: A higher consumption of fuel.

- Check Engine Light: Illumination of the malfunction indicator lamp (MIL).

Diagnosing the Issue

If you suspect a misfire, follow these steps:

-

Check for Codes: Use an OBD-II scanner to retrieve diagnostic trouble codes (DTCs). Misfire codes (P0300-P0308) can pinpoint the affected cylinder(s).

-

Visually Inspect Wires: Carefully examine the spark plug wires for any signs of damage, as described above.

-

Test Wire Resistance: Use a multimeter to measure the resistance of each spark plug wire. Compare the readings to the manufacturer’s specifications. High resistance indicates a faulty wire.

-

Inspect Spark Plugs: Remove the spark plugs and inspect them for signs of wear, fouling, or damage. Replace any plugs that are in poor condition.

Correcting the Problem

Once you’ve identified the source of the misfire, take the following corrective actions:

-

Replace Faulty Wires: Replace any spark plug wires that are damaged, have high resistance, or show signs of wear.

-

Correct Wiring Errors: If you find that the spark plug wires are connected incorrectly, immediately correct the wiring according to the firing order and cylinder layout.

-

Replace Spark Plugs: Replace spark plugs that are worn, fouled, or damaged.

-

Ensure Proper Connections: Double-check all connections to ensure they are secure and free from corrosion.

By meticulously following these steps, you can ensure that your Big Block Chevy’s spark plug wires are correctly connected and in good condition, maximizing engine performance and preventing potentially damaging misfires.

Having pinpointed each cylinder’s location and understood the distributor’s role in orchestrating the spark, it’s time to focus on the final link in the chain: the spark plug wires themselves.

These wires are the high-voltage conduits that deliver the precisely timed spark from the distributor to the spark plugs, igniting the air-fuel mixture and initiating the combustion process.

Connecting these wires correctly is not just important; it’s absolutely essential for proper engine operation.

Now, let’s explore the heart of the engine’s rhythmic pulse: the intricate dance between the crankshaft and camshaft. Understanding their synchronized movements is key to fully grasping how the Big Block Chevy firing order comes to life.

Crankshaft and Camshaft: The Timing Masters

The firing order of a Big Block Chevy isn’t just a random sequence; it’s a carefully engineered orchestration dictated by the precise interplay between the crankshaft and the camshaft.

These two components are the unsung heroes of internal combustion, working in perfect harmony to bring controlled explosions to life.

Let’s delve into how these timing masters control the engine’s combustion sequence.

The Crankshaft and Camshaft Partnership: Orchestrating the Combustion Sequence

The crankshaft and camshaft are mechanically linked, typically via a timing chain or timing gears. This connection ensures that their movements are synchronized.

The crankshaft’s primary function is to convert the linear motion of the pistons into rotational motion, which ultimately drives the vehicle.

The camshaft, on the other hand, controls the opening and closing of the intake and exhaust valves in each cylinder.

The lobes of the camshaft are precisely shaped to actuate the valves at specific points in the engine’s cycle.

The camshaft rotates at exactly half the speed of the crankshaft in a four-stroke engine. This 2:1 ratio is crucial for coordinating the valve timing with the piston’s movements over the four strokes: intake, compression, combustion, and exhaust.

It is this precise synchronization that dictates the firing order.

Piston Movement and the Firing Order: A Rhythmic Relationship

The firing order (1-8-4-3-6-5-7-2 for the Big Block Chevy) is directly related to the position of each piston within the engine.

As the crankshaft rotates, it raises and lowers the pistons in a specific sequence.

The camshaft, in turn, opens and closes the valves to allow the air-fuel mixture to enter the cylinder and the exhaust gases to escape.

The design of the crankshaft dictates the order in which the pistons reach Top Dead Center (TDC).

For example, in the Big Block Chevy, cylinder number one reaches TDC first, followed by cylinder number eight, and so on, according to the firing order.

The camshaft’s lobes are designed to open the intake valve for each cylinder just before its piston begins its downward intake stroke.

After the air-fuel mixture is compressed and ignited, the camshaft opens the exhaust valve as the piston moves upward on the exhaust stroke.

This carefully timed sequence ensures that each cylinder fires at the optimal moment for maximum power and efficiency.

Visualizing Crankshaft and Camshaft Timing

Understanding the relationship between crankshaft and camshaft timing is greatly aided by a visual representation.

Imagine a diagram showing the crankshaft rotating and the camshaft rotating at half that speed.

The diagram would also show the pistons moving up and down in their cylinders, with each piston reaching TDC at a different point in the crankshaft’s rotation.

Overlaid on this would be the camshaft lobes, opening and closing the valves at precise moments in relation to the piston’s position.

Such a diagram would clearly illustrate how the firing order is a direct result of the mechanical relationship between the crankshaft, camshaft, and pistons.

An animated simulation can further clarify the relationship, showing the dynamic movement of these components in real-time.

These visualizations reinforce the understanding that the firing order is not an arbitrary sequence, but rather a meticulously engineered process.

Having pinpointed each cylinder’s location and understood the distributor’s role in orchestrating the spark, it’s time to ensure that all the adjustments and connections culminate in the precisely timed combustion events essential for optimal engine performance. Verifying engine timing, especially after distributor work or any adjustments, is a non-negotiable step in fine-tuning your Big Block Chevy. Let’s delve into the processes and implications involved in this crucial procedure.

Engine Timing Verification: Ensuring Accuracy

Verifying engine timing is a critical step after any adjustments to the distributor or its replacement. This ensures that the spark plugs are firing at precisely the correct moment relative to the piston’s position in the cylinder. Accurate timing is paramount for optimal engine performance, fuel efficiency, and longevity.

The Verification Process: A Step-by-Step Guide

The process involves several key steps:

- Preparation: Ensure the engine is at operating temperature. Locate the timing marks on the crankshaft pulley or harmonic balancer and the corresponding timing pointer on the engine. Clean these marks to ensure they are clearly visible.

- Connecting the Timing Light: A timing light is an essential tool for this process. Connect the timing light’s power leads to the battery (positive and negative). Attach the inductive pickup to the number one spark plug wire.

- Locating Timing Marks: The crankshaft pulley or harmonic balancer will have timing marks, usually in degrees BTDC (Before Top Dead Center) and ATDC (After Top Dead Center). The timing pointer indicates the current timing setting.

- Reading the Timing: With the engine running at the specified idle speed, point the timing light at the timing marks. The light will flash each time the number one spark plug fires. Observe where the timing pointer aligns with the marks on the pulley. This indicates your current timing setting.

- Adjusting Timing (If Necessary): If the timing is not within the manufacturer’s specifications, loosen the distributor hold-down clamp. Gently rotate the distributor until the timing marks align correctly. Tighten the clamp and recheck the timing to ensure it hasn’t shifted during tightening.

Utilizing a Timing Light to Check Base Timing

A timing light is indispensable for checking base timing accurately. This stroboscopic light flashes in sync with the firing of the spark plug, effectively "freezing" the motion of the crankshaft pulley. This allows you to visually align the timing mark on the pulley with the timing pointer on the engine.

Understanding Timing Light Features

Modern timing lights often come with advanced features such as:

- Adjustable Timing Advance: This allows you to check timing at higher RPMs without manually calculating the advance.

- Digital Displays: Some timing lights feature digital displays that show the RPM and timing advance, making the process more precise.

Setting Base Timing

Base timing refers to the engine timing at idle speed. Refer to your vehicle’s service manual for the correct base timing specification.

- Warm-up the engine until it reaches normal operating temperature.

- Locate and disconnect the vacuum advance hose from the distributor. Plug the hose to prevent vacuum leaks.

- Connect the timing light as described earlier.

- Start the engine and let it idle.

- Point the timing light at the crankshaft pulley and timing pointer.

- Observe the alignment of the timing marks.

- Adjust the distributor until the timing mark aligns with the specified degree on the timing pointer.

- Tighten the distributor hold-down clamp.

- Reconnect the vacuum advance hose.

- Recheck the timing to ensure it remains correct after tightening the clamp.

Impact of Incorrect Timing

Incorrect timing can have significant repercussions on your engine’s performance and longevity.

Detrimental Effects of Incorrect Timing

- Reduced Power and Performance: When the timing is off, combustion doesn’t occur at the optimal moment, leading to a decrease in power and acceleration.

- Poor Fuel Economy: Inefficient combustion wastes fuel, resulting in lower MPG.

- Engine Knock or Detonation: Advanced timing can cause the air-fuel mixture to ignite too early, leading to engine knock or detonation, which can severely damage pistons and connecting rods.

- Overheating: Retarded timing causes the exhaust valves to open later, which can lead to unburned fuel being sent to the exhaust system and excessive heat buildup, potentially causing valve damage and overheating.

- Increased Emissions: Inefficient combustion also increases harmful emissions.

Potential Engine Damage

Severe engine damage can occur if timing issues are ignored, including:

- Piston Damage

- Connecting Rod Failure

- Valve Damage

- Head Gasket Failure

Regularly checking and correcting your engine timing will safeguard your Big Block Chevy, ensuring it delivers the power and reliability you expect for years to come. Accurate timing is not merely a fine-tuning aspect; it’s a cornerstone of engine health and performance.

Having pinpointed each cylinder’s location and understood the distributor’s role in orchestrating the spark, it’s time to ensure that all the adjustments and connections culminate in the precisely timed combustion events essential for optimal engine performance. Verifying engine timing, especially after distributor work or any adjustments, is a non-negotiable step in fine-tuning your Big Block Chevy. Let’s delve into the processes and implications involved in this crucial procedure.

Troubleshooting Firing Order Issues: Symptoms and Solutions

A Big Block Chevy running rough? Performance feeling sluggish? An incorrect firing order is a prime suspect. Diagnosing and rectifying these issues is crucial, not just for restoring power, but also preventing potential engine damage. This section provides a guide to recognizing symptoms, systematically verifying the firing order, and avoiding common pitfalls.

Recognizing the Symptoms of a Misfire

The most immediate sign of a firing order problem is usually a noticeable misfire.

This feels like a stumble or hesitation in the engine, especially under load. Instead of a smooth, consistent power delivery, you’ll experience a jerky or uneven acceleration.

Poor Engine Performance and Reduced Power

Beyond the obvious misfire, an incorrect firing order will severely impact overall engine performance. You’ll likely notice:

- A significant reduction in power, especially at higher RPMs.

- Poor throttle response, making the engine feel sluggish and unresponsive.

- Reduced fuel efficiency, as the engine struggles to burn fuel effectively.

Unusual Engine Noises

An engine with the incorrect firing order might produce unusual sounds. These can include:

- Popping or backfiring sounds coming from the exhaust or carburetor.

- A general "roughness" or vibration that wasn’t present before.

Diagnosing Rough Idle

Another indicator is a rough idle. The engine may shake or vibrate excessively when idling. This is because the cylinders are not firing in the correct sequence to maintain a smooth rotational balance.

Step-by-Step Verification and Correction

Suspect a firing order issue? Follow these steps for accurate verification and correction:

-

Visual Inspection: Begin by visually inspecting all spark plug wires. Ensure they are securely connected to both the spark plugs and the distributor cap terminals. Look for any signs of damage, such as cracks, burns, or loose connections.

-

Cylinder Identification: Confirm you can accurately identify each cylinder number on your Big Block Chevy engine. Refer to a reliable diagram to avoid confusion, as incorrect identification is a common mistake.

-

Distributor Cap Check: Verify the distributor cap terminals correspond to the correct cylinder numbers based on the 1-8-4-3-6-5-7-2 firing order. Ensure the cap is properly seated and free of cracks or damage.

-

Timing Light Verification: Use a timing light to check the ignition timing. While this won’t directly confirm the firing order, it can reveal underlying timing issues that might be contributing to the problem.

-

Firing Order Sequence Check: Methodically trace each spark plug wire from the distributor cap to the corresponding cylinder. Double-check that they follow the correct 1-8-4-3-6-5-7-2 sequence.

-

Wire Swapping (Carefully!): If you suspect a specific wire is misplaced, carefully swap it with the correct one. Start the engine and observe if the misfire improves. Only do this one wire at a time to avoid further complications.

-

Compression Test: If the firing order seems correct, but the misfire persists, perform a compression test on each cylinder. Low compression in one or more cylinders can mimic firing order problems.

Common Mistakes to Avoid

Working with the firing order can be tricky. Here are some common pitfalls to avoid:

Incorrect Cylinder Identification

This is the most frequent mistake. Double-check cylinder numbers before making any connections. Refer to a reliable engine diagram and verify the orientation on your specific engine.

Assuming Wire Condition

Don’t assume spark plug wires are in good condition. Even if they look fine, they may have internal damage or high resistance. Use a multimeter to check the resistance of each wire and replace any that are outside the specified range.

Neglecting Distributor Cap Condition

A cracked or damaged distributor cap can cause misfires and firing order issues. Inspect the cap carefully for any signs of wear or damage, and replace it if necessary. Ensure the terminals are clean and free of corrosion.

Ignoring Base Timing

Incorrect base timing can mask or exacerbate firing order problems. Always verify and adjust the base timing after making any changes to the distributor or spark plug wires.

Big Block Chevy Firing Order FAQs

This FAQ section addresses common questions related to the Big Block Chevy firing order discussed in the main guide.

Why is knowing the firing order for a big block Chevy important?

Knowing the correct firing order is critical for proper engine operation. An incorrect firing order will cause misfires, poor performance, and potentially engine damage. Proper ignition timing relies on the correct firing sequence.

What is the standard firing order for big block Chevy engines?

The standard firing order for big block Chevy engines is 1-8-4-3-6-5-7-2. Always double-check your specific engine application to confirm.

Does the firing order change based on the cubic inch displacement of the big block Chevy?

No, the firing order for a big block Chevy generally remains the same (1-8-4-3-6-5-7-2), regardless of displacement (e.g., 396, 454, 502). However, there are always exceptions, especially with custom-built or modified engines, so verify.

How can I easily remember the firing order for a big block Chevy?

A simple way to remember the standard firing order for big block Chevy engines is the mnemonic: "One Eight Four Three Six Five Seven Two." Writing it down also helps.

Alright, gearheads! Hopefully, this deep dive into the firing order for big block chevy helped you tune up your knowledge. Now go wrench responsibly and keep those big blocks rumbling!